I was having trouble with tall prints on the Automated Build Platform. I cut the belt off of it and removed the rollers and motor. Then I covered the surface with Kapton tape. I ordered an aluminum build plate, but I am waiting for it to arrive from the UK (MakerBot was sold out). My print quality is already better and my rafts separate from the print much more easily.

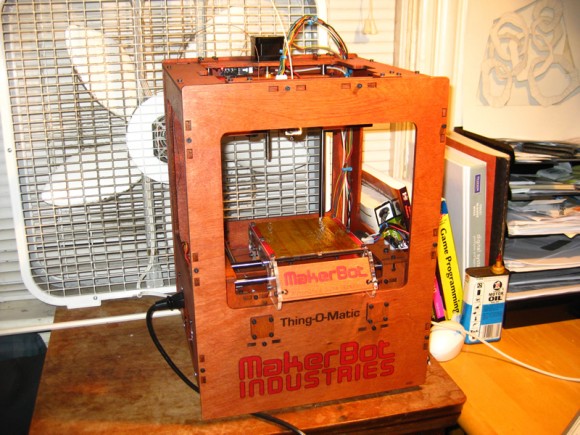

I have assembled my Thing-o-matic and she is now operational. However, she had some issues along the way. Here is what the problems were and how I fixed them.

My Configuration:

- MK7 extruder

- ABP

- MakerBot Motherboard v2.x (Gen4) with Mega 2560 (latest version of firmware)

- Extruder Controller v.3.X (Gen 4) (latest version of firmware)

- ReplicatorG 0028

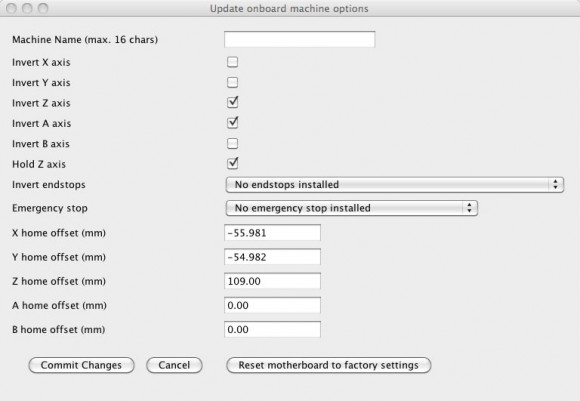

System Information ReplicatorG version: 0028 Java version: 1.6.0_29 Machine Profile Name: Thingomatic w/ ABP and Stepstruder MK7 Driver Type: Makerbot4GAlternate Name: Thingomatic w/ ABP and Stepstruder MK7 Motherboard firmware version: Unknown v3.1 Motherboard communication statistics Number of packets received from the USB interface:0 Number of packets sent over the RS485 interface:147081 Number of packets sent over the RS485 interface that were not responded to:5 Number of packet retries attempted:25 Number of bytes received over the RS485 interface that were discarded as noise:0

Problem 1: When trying to print, Bot stops after homing

- When I try to print, the axes home, then stop. All red LEDs are on for each of the mechanical endstops.

- After about 4 minutes, there is an audible click and the red light turns on the safety cutoff. Nothing else happens.

What I have tried:

1. I ran the calibration script.

2. I tried making the offset settings for each axis 2mm less. No change.

Solution:

The temp sensor was too hot. I added a second layer of ceramic insulation to the Mk7 head under the temp sensor (in addition to the layer that MakerBot says to add). This solved the “homing, then stopping” problem. http://www.makerbot.com/docs/thingomatic/instructions-for-educators/stepstruder-mk7-assembly/ 3/4 of the way down the page, under the “Insulate the Heater” heading, the process is described. If you have already taped up your print head, untape it, remove the temp sensor, add a second layer of insulation between the heater block and the temp sensor. Re-tape.

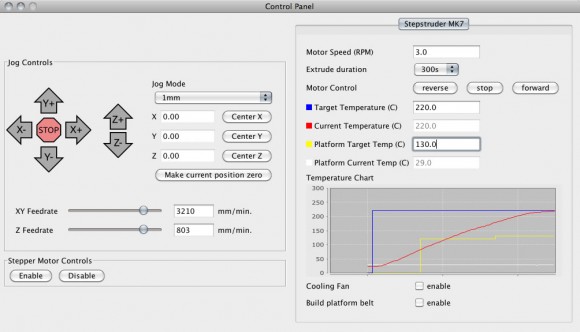

Problem 2: ABP motor does not work, platform will not heat

- The ABP will not heat and the ABP motor will not move.

What I have tried so far:

- Checking the wiring on the extruder controller. (many times). It is wired up like this: http://www.makerbot.com/docs/thingomatic/instructions-for-educators/electronics/

- When I click the “enable” boxes for the build platform belt and the cooling fan, the appropriate LEDs light up on the extruder board, but nothing happens.

Solution:

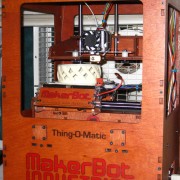

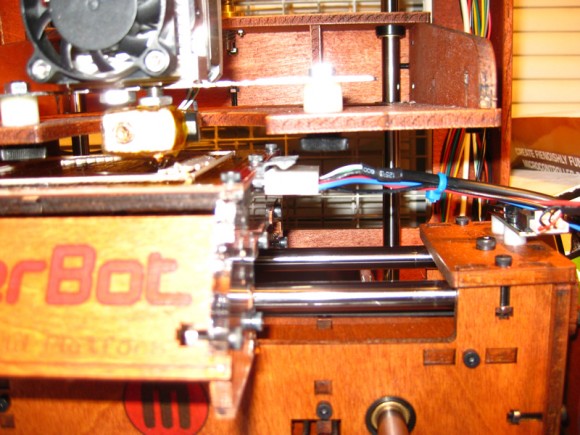

I had plugged the cable in backwards into the ABP. The cable gets plugged into the ABP with the ramp side up and the holes facing down. The platform heated after I reversed the cable orientation. I found this orientation hard to see in the MakerBot build instructions. See pic below for the right orientation.

Right Way