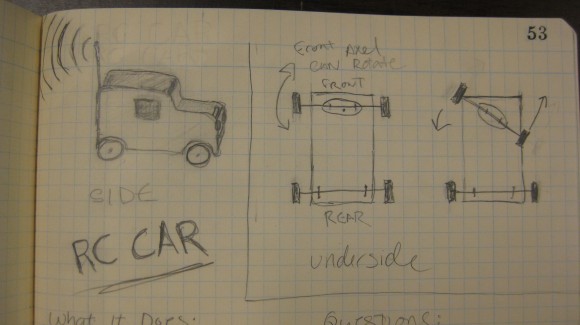

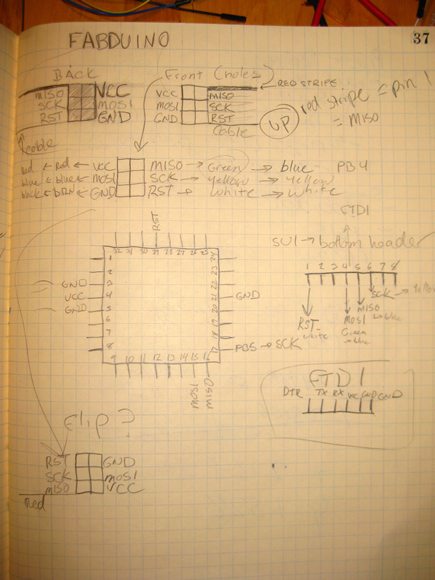

This week at Fab Academy we are planning our final projects. I am creating a digitally fabricated RC car. First I defined my all the system components, how they would interact with each other and what the logic / voltage levels needed to be throughout that system.

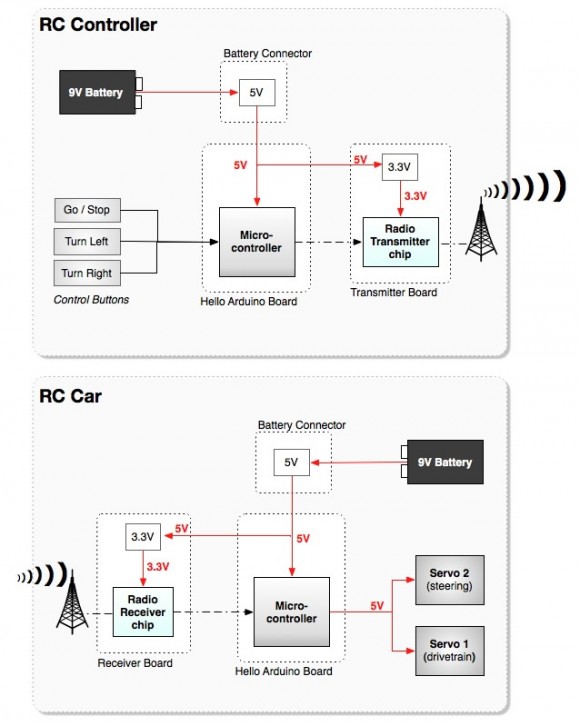

Logic Levels / Radio – Functional Block Diagram

What Will It Do?

- Drive forward / stop

- Turn left / right

- Use radios to control the car wirelessly.

Who’s Done What Beforehand?

- David Mellis made pressfit cars – this one needs to be more of an enclosure to house the electronics

- JeeLabs: http://jeelabs.org/ has created some code and designs that I plan to modify and use with the Hope RF radios.

What Materials and Components Will Be Required?

- 2 servos

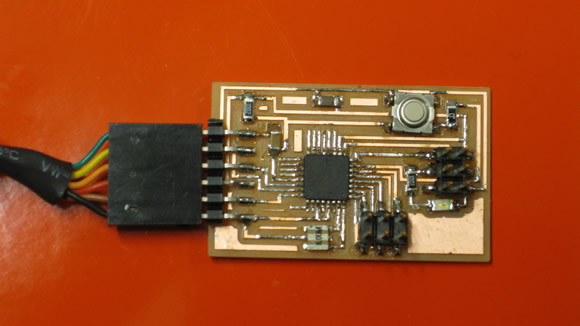

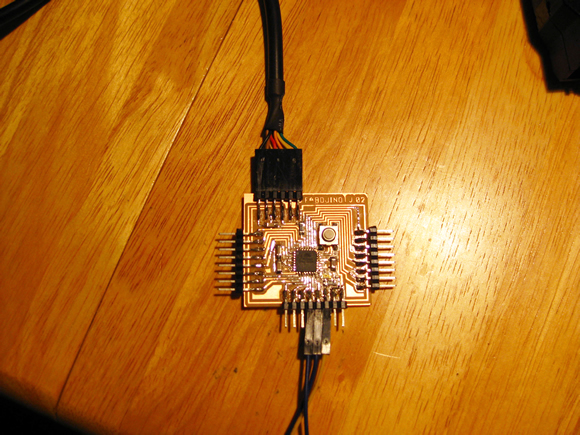

- 2 radio boards (utilizing the Hope RF radios)

- 1 or 2 Arduino boards (hello Arduino boards)

- Masionite

- LEDs (possible decoritive addition)

- Acrylic (possible decoritive addition)

- Possibly plastic to cast parts (possible decoritive addition)

- Metal rods for axels?

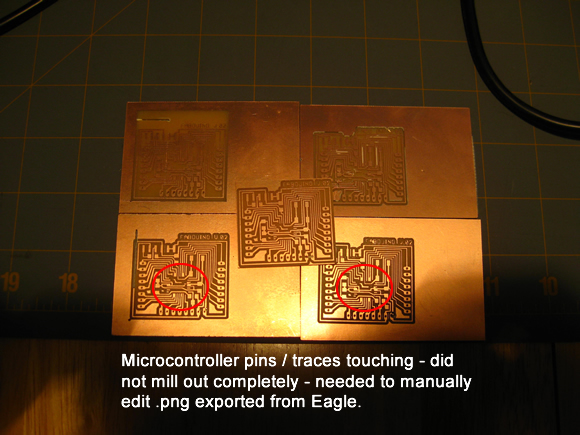

- copper-clad PCB stock

- Various components already in the inventory

How Much Will It Cost?

- $0 – $20 Most parts already in the inventory.

- Need to purchase Hope RF radios – $12.00 for a pair.

- Need to purchase a few additional non-standard, non-inventory components from Digikey ($10.00 + shipping).

What Parts and Systems Will Be Made?

- Connect the radio boards to the Arduino

- Figure out how to issue commands to control the car

- Turn lights on and off

What Processes Will Be Used?

- Laser-cut press fit for the car body (possibly being replaced by molded shell / parts)

- Milled circuit boards.

- Molded parts for wheels / accessories

What Tasks Need to Be Completed?

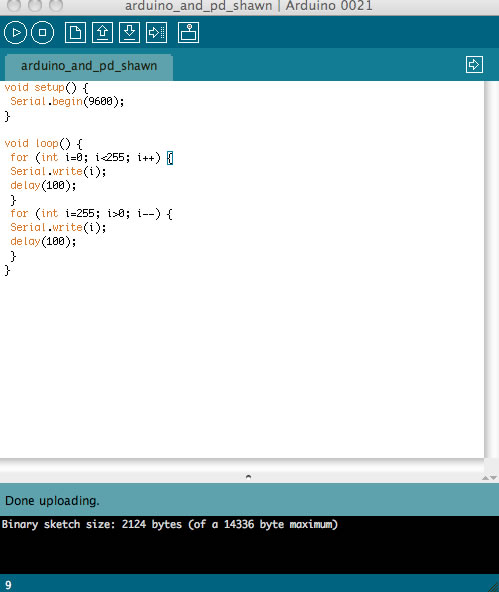

- Need to investigate how to get the boards to talk to each other.

- Control with computer keys at first.

- Would like to eventually add a wireless joystitck control box.

What Is The Schedule?

- This Week –> Design the car and investigate the how to talk to the radios

- Next Week –> Troubleshoot the project, work on the control structure.

How Will It Be Evaluated?

- Can the radios talk to each other?

- Do the controls work?