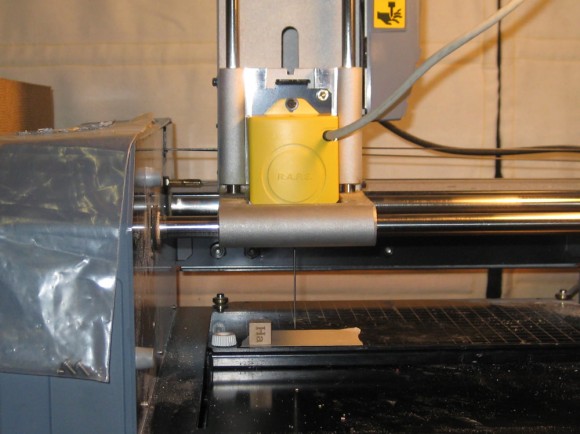

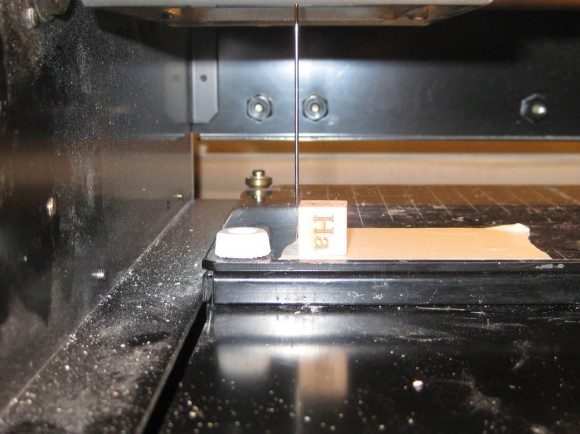

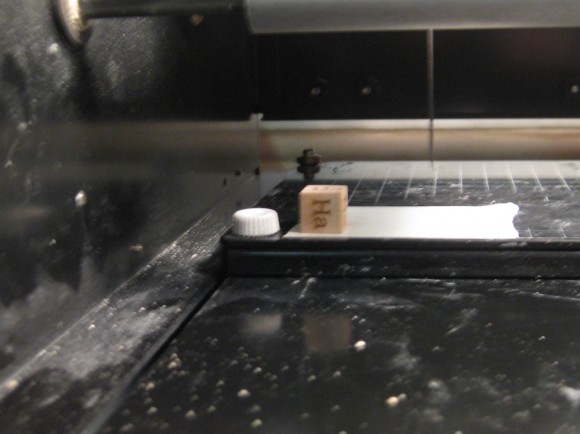

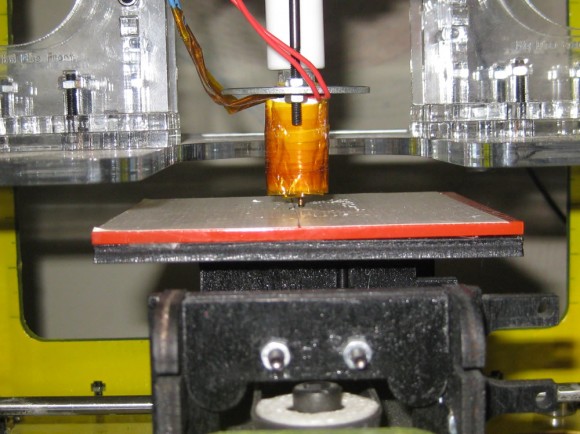

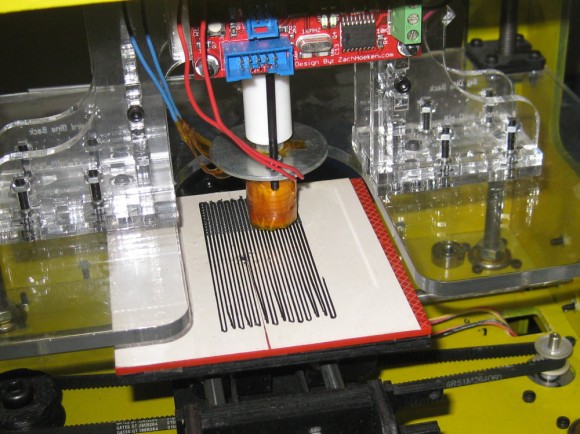

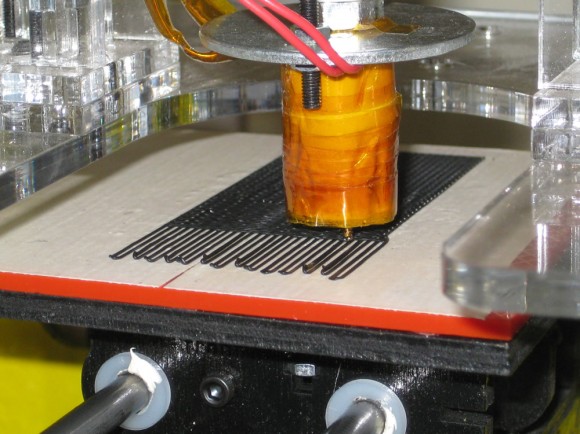

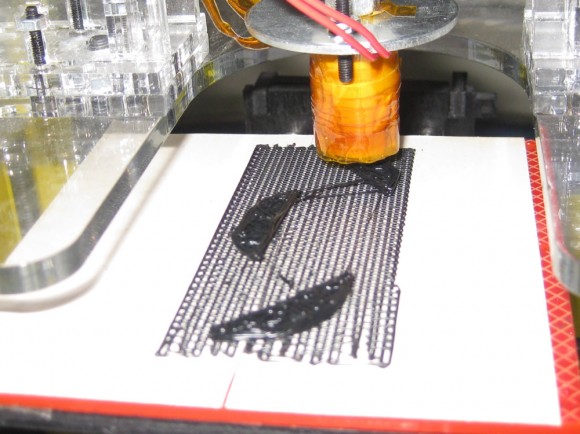

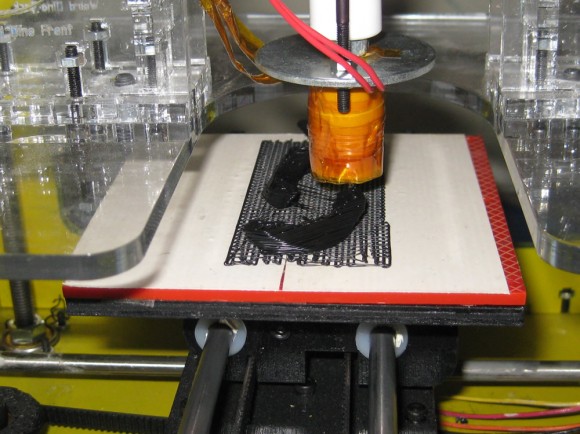

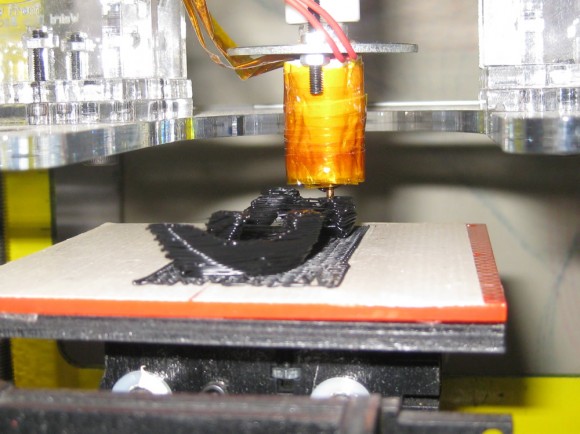

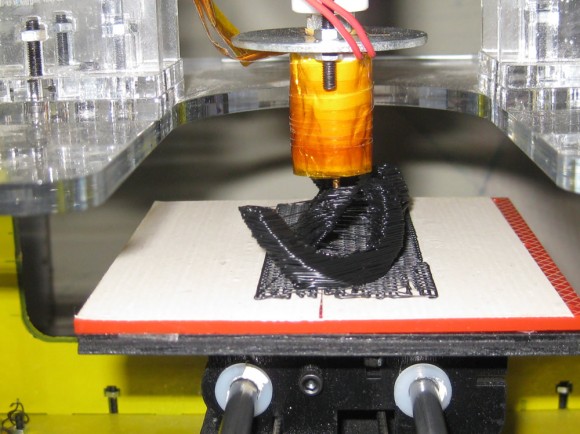

After we put the spindle together – Shawn and I tested the Mantis to see if it would respond to commands. It looks like Fab Academy AS220 (with a huge effort on Noah’s part) put machine together properly.

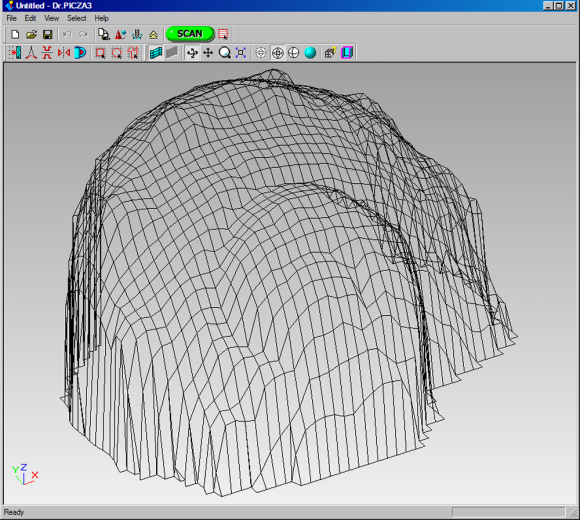

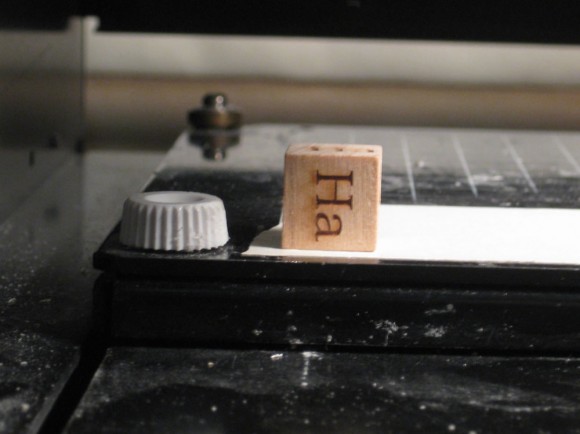

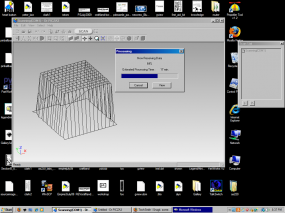

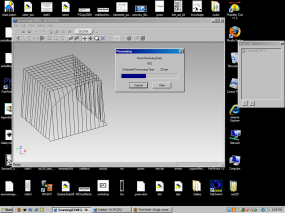

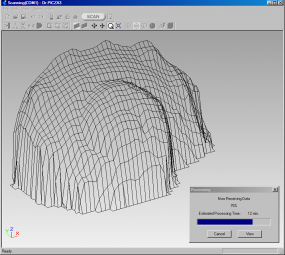

The Mantis responded to the following commands (see screenshots) and responded well. The next step is to figure out how to feed an .rml file into the software. (in progress). After that we need to mill a board on the Mantis and see how it turns out.