Puppetmaster Overview

My final project for Fab Academy is a universal remote I am calling PuppetMaster, due to its ability to control out of reach objects / devices using the fingers. This is the revised final project proposal – the first proposal was overly ambitious and encompassed too many sensor types in too short of a time period.

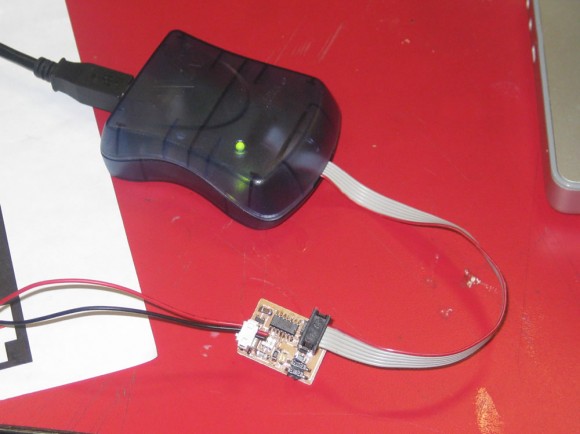

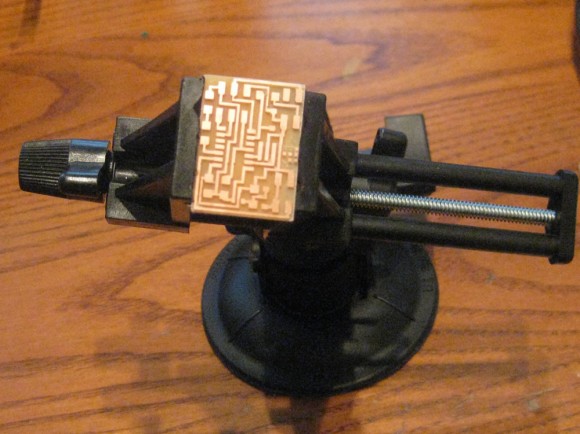

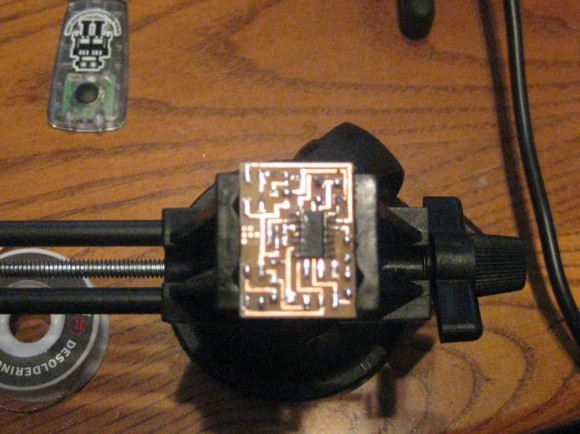

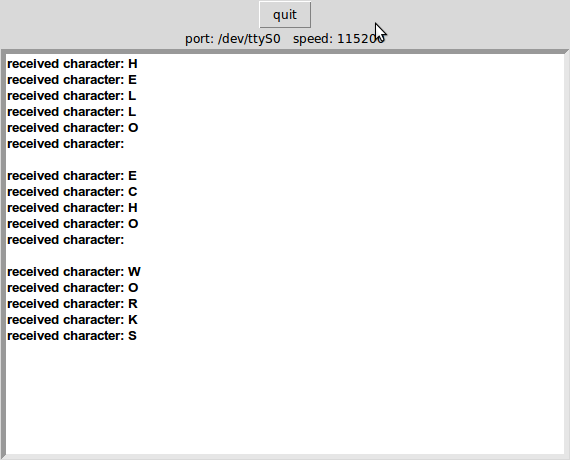

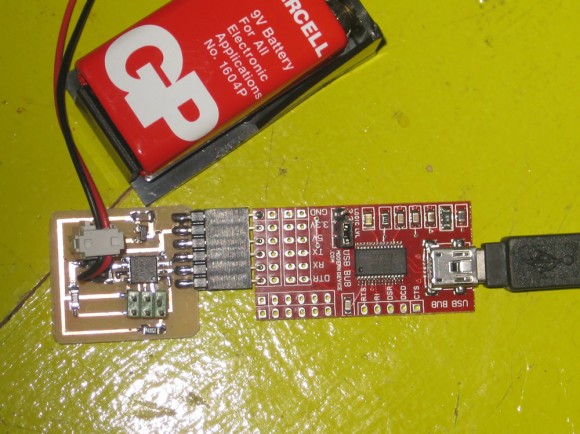

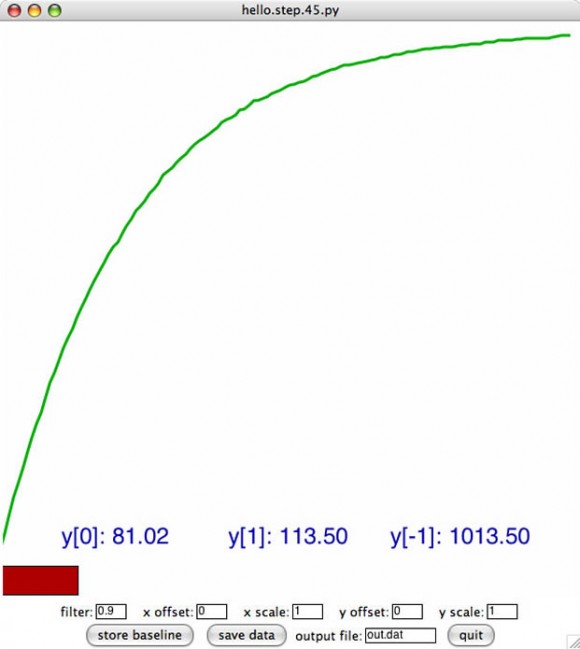

First Working Prototype: The first working prototype (illustrated in the PuppetMaster v.1-v.2 [capacitive sensing] post) uses thin copper sheets to create a capacitive sensor between the index finger and the thumb.

For Fab 6: By Fab Academy graduation I propose that PuppetMaster will consist of a fabbed board that reads gestural input from accelerometers.

Overall Project Goals / Design Considerations:

- Create a remote control that takes input from finger movements / gestures

- Remote is small and wearable (will likely look like a bracelet or a watch) with connections to the fingertips.

- Remote is comfortable enough for long-term wear, will help to relieve hand / joint fatigue

Project Plan

Short Term Project Stages (Completed by Fab 6)

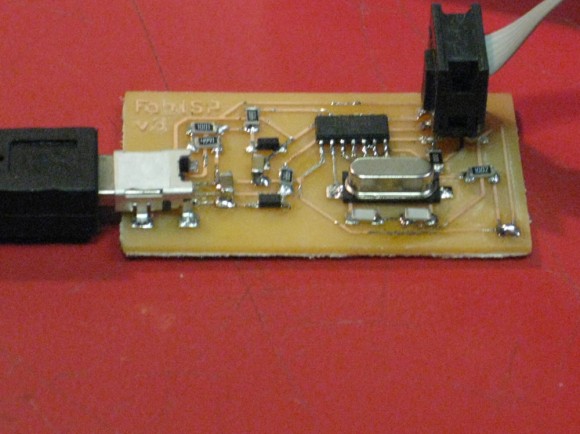

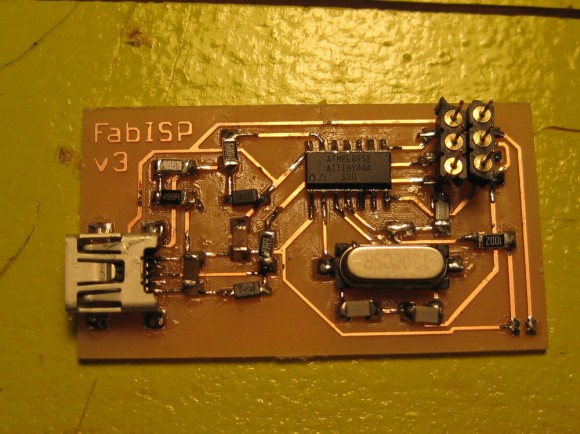

All board(s) will be fabbed, using the standard fab inventory parts with a few exceptions, (the sensors used in the later stages).

The First Stage [capacitive sensing]

- Completed June 2nd – consists of using capacitive sensing as input data.

The Second Stage [ accelerometer input]

- Completion before Fab 6 in August, will include the addition of accelerometer on each finger to record control gestures.

- Simple gestures will be used for input controls.

Long Term Project Stages (Work in Progress – NOT for Fab 6)

- Additional stages (to follow in the in the Fall) will include one mode of control (IR) but other modes (radio, bluetooth) will be added as the project progresses. (See stages outlined in the table below.)

- Eventually, a dial or switching mechanism will be added to switch between the modes. Although the other modes of control mentioned above will be explored, the gestural input will be the primary focus.

- In the final version of this prototype, the user of PuppetMaster will be able to input information via gestures and remote control objects by using sensors embedded in the fingertips.

- These additional modes (combined with the necessary code) will allow the user to control almost any device with hand gestures. I also want to develop a complete gestural language (possibly based on sign language)in tandem with the addition of 6-axis sensors (3 axis gyro, 3 axis accelerometer) to the device.

Revised Project Schedule:

| Stage | Description | Deliverable | Date Range | Board Version |

| Short Term – For Fab 6 | ||||

| 1.0 | Capacitive Sensing | working capacitive sensing prototype | Complete on 6/2/2010 | v.1 – v.2 |

| 2.0 | 6-axis Sensors (gyro, accelerometer) | accelerometer prototype | 06/02/2010 – 09/16/2010 | v.3 – |

| 3.0 | Basic gestural language | A few mapable gestures that can be read by the computer / another device | 06/02/2010 – 09/16/2010 | v.3 – |

| Long Term – Future Improvements to make the remote “universal†| ||||

| 4.0 | Infrared | infrared remote prototype | 05/16/2010 – TBD | |

| 5.0 | Radio Control | infrared remote prototype + radio control | 07/01/2010 – TBD | |

| 6.0 | Bluetooth | infrared remote prototype + radio control + bluetooth | 08/20/2010 – TBD | |

| 7.0 | Complex gestural Language | Full gestural language mapped to the 6-axis sensors | 07/01/2010 –TBD | |