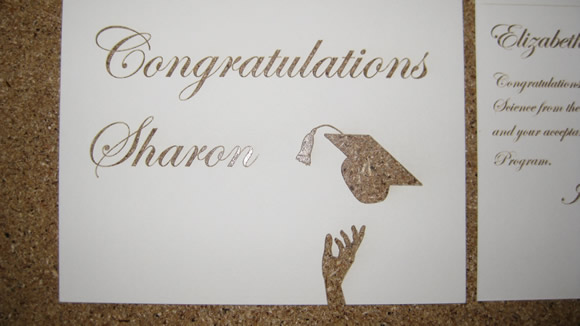

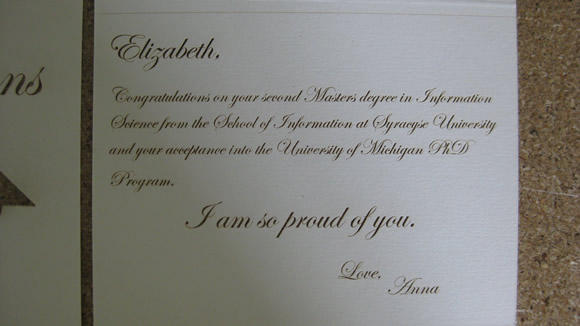

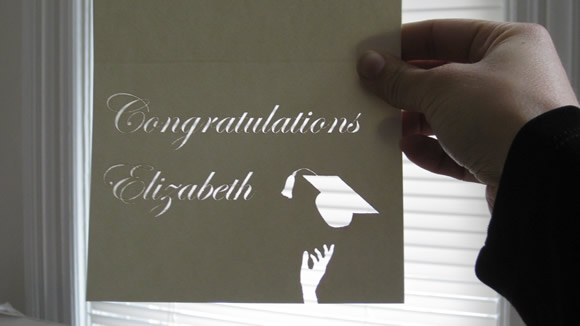

All my sisters are now college graduates (with at least 1 degree). Congratulations to Sharon Kaziunas for graduating from Bryn Mahr College with her BA and to Elizabeth Kaziunas who graduated from Syracuse University with her MA in Information Science. We now have two Masters of Information Science in the family.

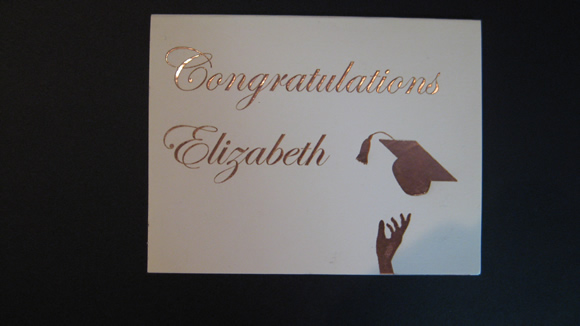

I thought I would commemorate the occasion by laser cutting them each a personalized graduation card.

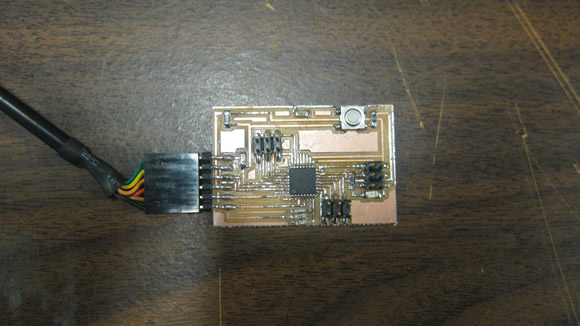

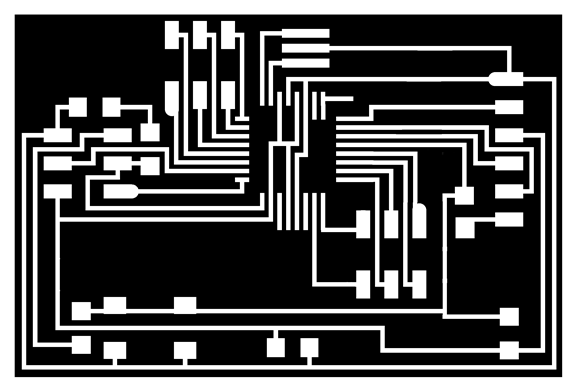

How The Cards Were Made

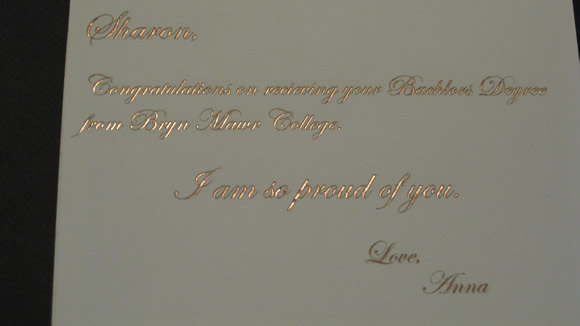

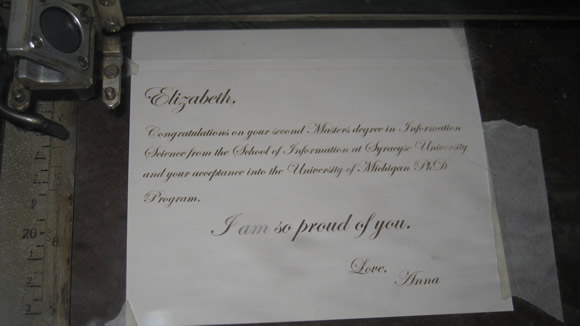

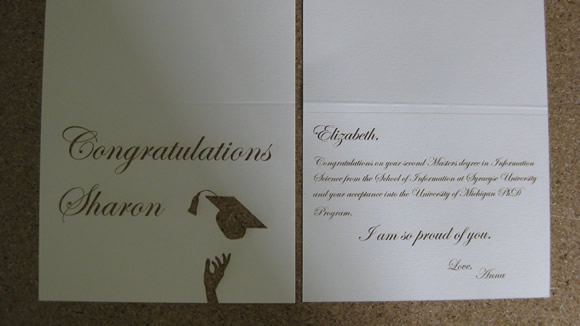

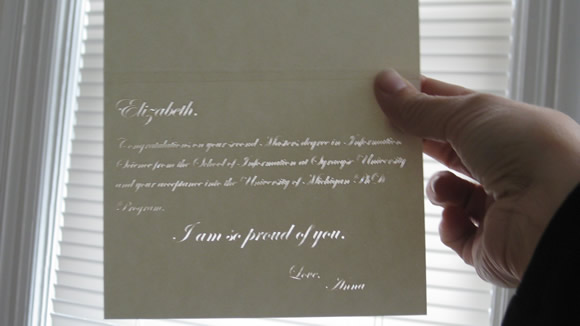

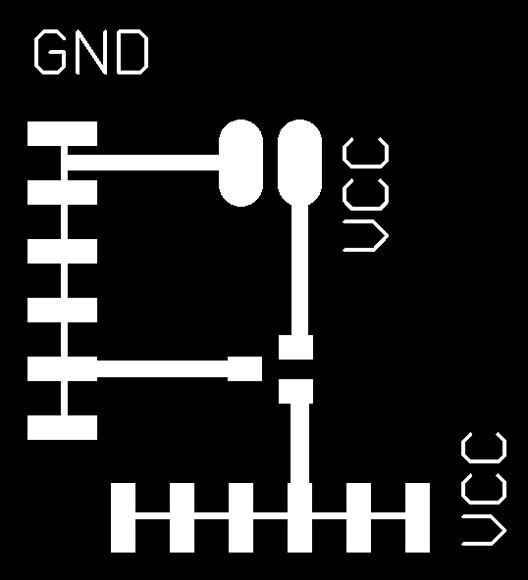

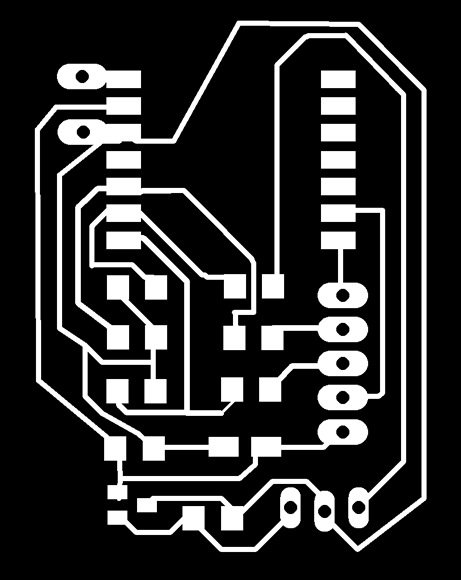

The cards were etched on the laser cutter using a “wood” setting. This removed the paper material under the etch, leaving a cut out area for both the text and the image. You can see in the pictures below that the paper was removed during the etch. I had to use a x-acto knife a little to remove some bits of paper that hung on.

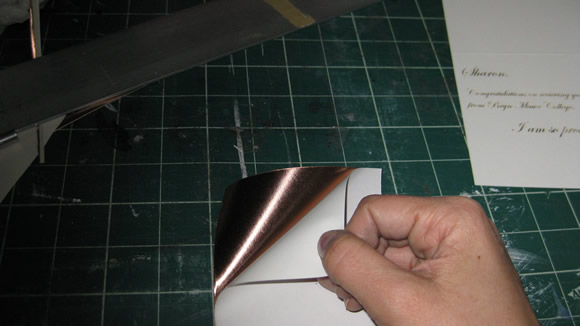

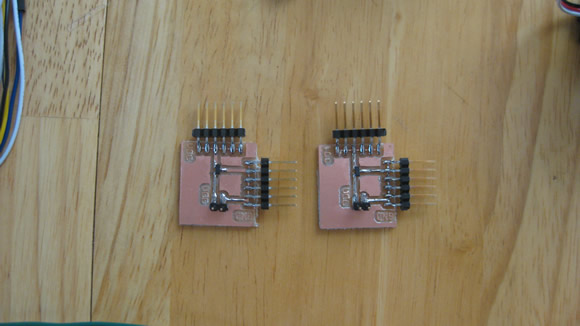

The cards are made of two layers of paper (shown below). The front of the card and the inside of the card. I put them together this way so I could sandwich the foil in the middle of the card and only have it showing through the gaps in the lettering.

I used two pieces of copper foil per card, cut it to the dimensions of the folded card. I put the cards together (without adhesive) with the front “congratulations” and the inside “text’. Then, I removed the adhesive backing and stuck the foil behind the lettering. I then used a glue stick to adhere the two card sections together.